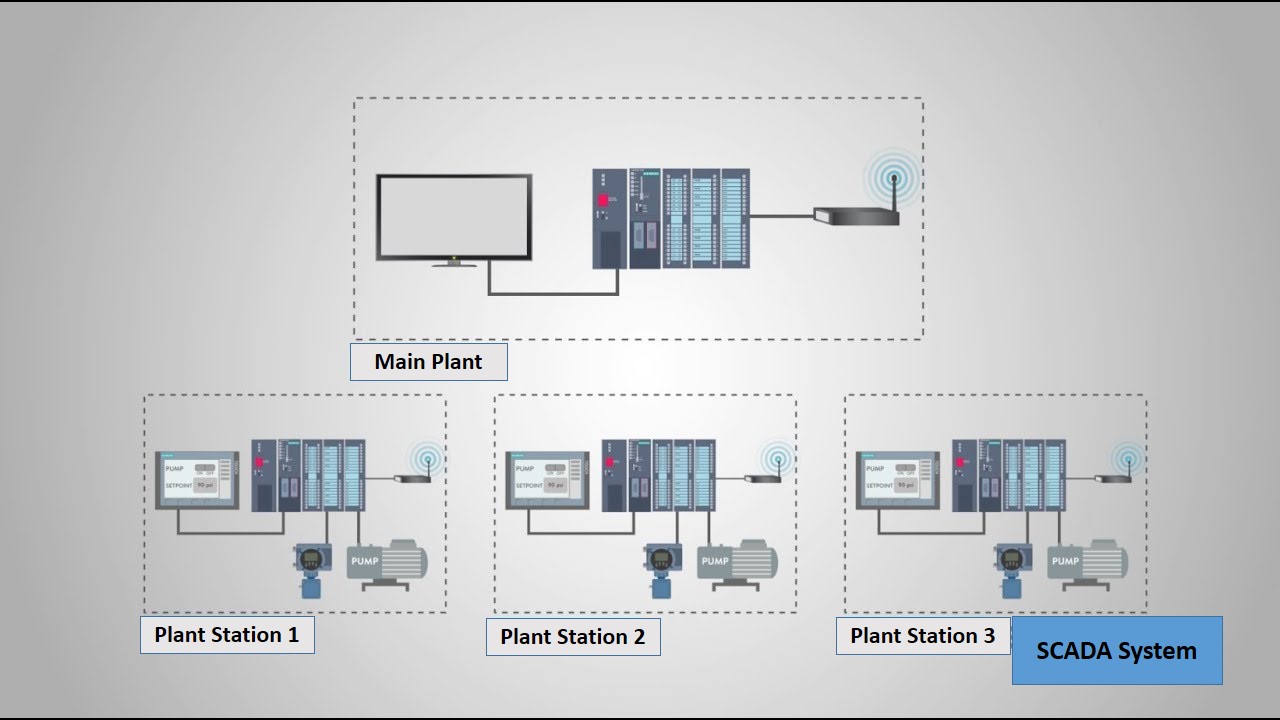

Supervisory Control and Data Acquisition

Optimizing Performance Through SCADA

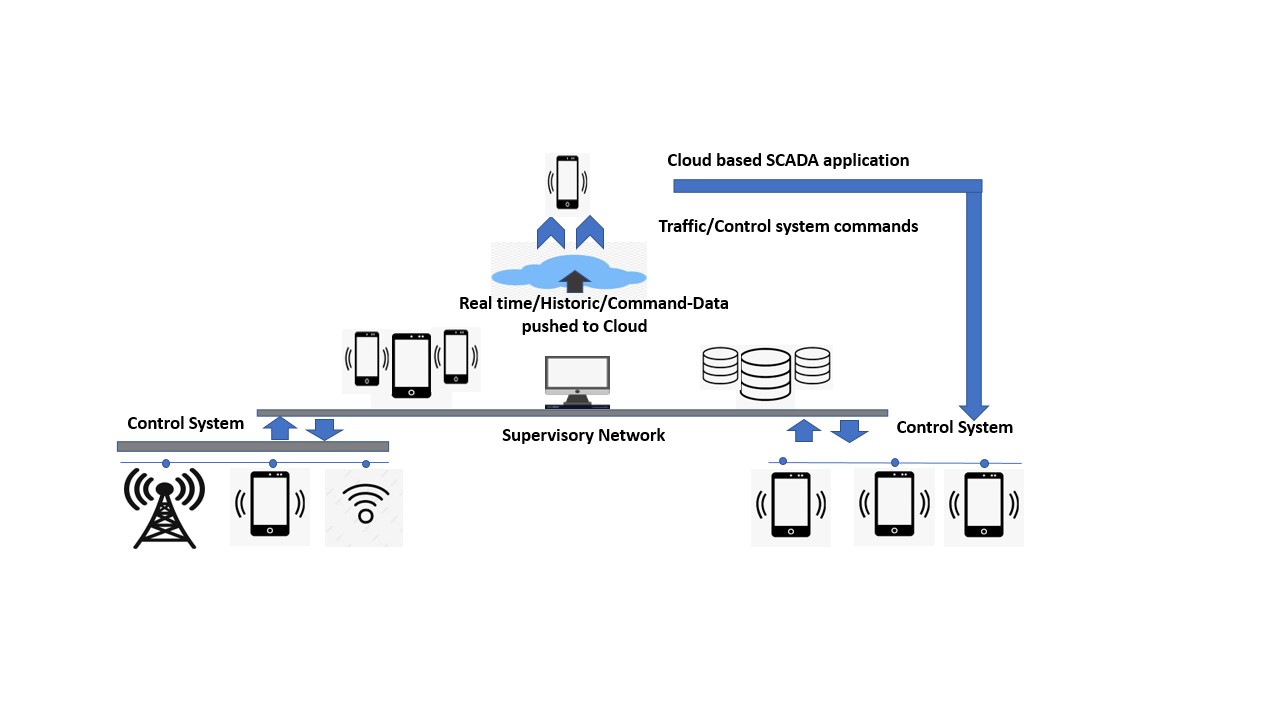

Many power, electric, and water companies still rely on manual labor for measurements and adjustments. SCADA systems can automate these tasks easily.

Automation with SCADA cuts labor costs and reduces measurement errors. The system offers benefits like redundancy adjustments, stable backups, and a secure alarm system.

Instead of manual checks, SCADA uses scripts to detect and fix system issues. This prevents outages and quickly resolves any that occur. If an outage happens, SCADA’s distributed database helps workers locate the failure instantly.

SCADA revolutionizes operations by automating control and monitoring tasks. It replaces manual labor with real-time data collection and analysis, enhancing efficiency and accuracy. SCADA systems reduce labor costs, minimize errors, and provide stable backups and secure alarms. They use automated scripts to detect and address issues promptly, preventing system outages. In case of an unexpected failure, SCADA’s distributed database quickly identifies the problem’s location, allowing for swift resolution. By integrating SCADA, businesses can achieve greater reliability, improved performance, and streamlined operations, making it a crucial tool for modern industrial management.